To address the technical aspect of improving our existing business processes, we implemented a comprehensive solution that involved close collaboration with our business users.

First, we interacted with the business to understand their specific functional specifications, mappings, and extract logics. We then gathered the business requirements from the business users and prepared technical documents for the migration of data from the source system to SAP.

Next, we migrated the data to HANA, and wrote LSMW programs to load data to SAP. We also developed data services jobs for transforming and enriching the data, which helped us to ensure that the data was accurate and relevant for our business operations.

To ensure that we were implementing the best practices and providing the best possible solutions, we installed and configured Business Objects Data Services (BODS), as well as other EIM Business Objects product family. We used BODS to profile and validate the data, which helped us to identify any issues or discrepancies that needed to be addressed.

We also prepared technical specifications and knowledge transfer documents, which helped us to ensure that our solution was well-documented and easy to understand. Additionally, we wrote SQL scripts to analyze and validate the data, and developed a process layer using ABAP/LSMW, Oracle RDBMS, SQL Server, and SAP HANA.

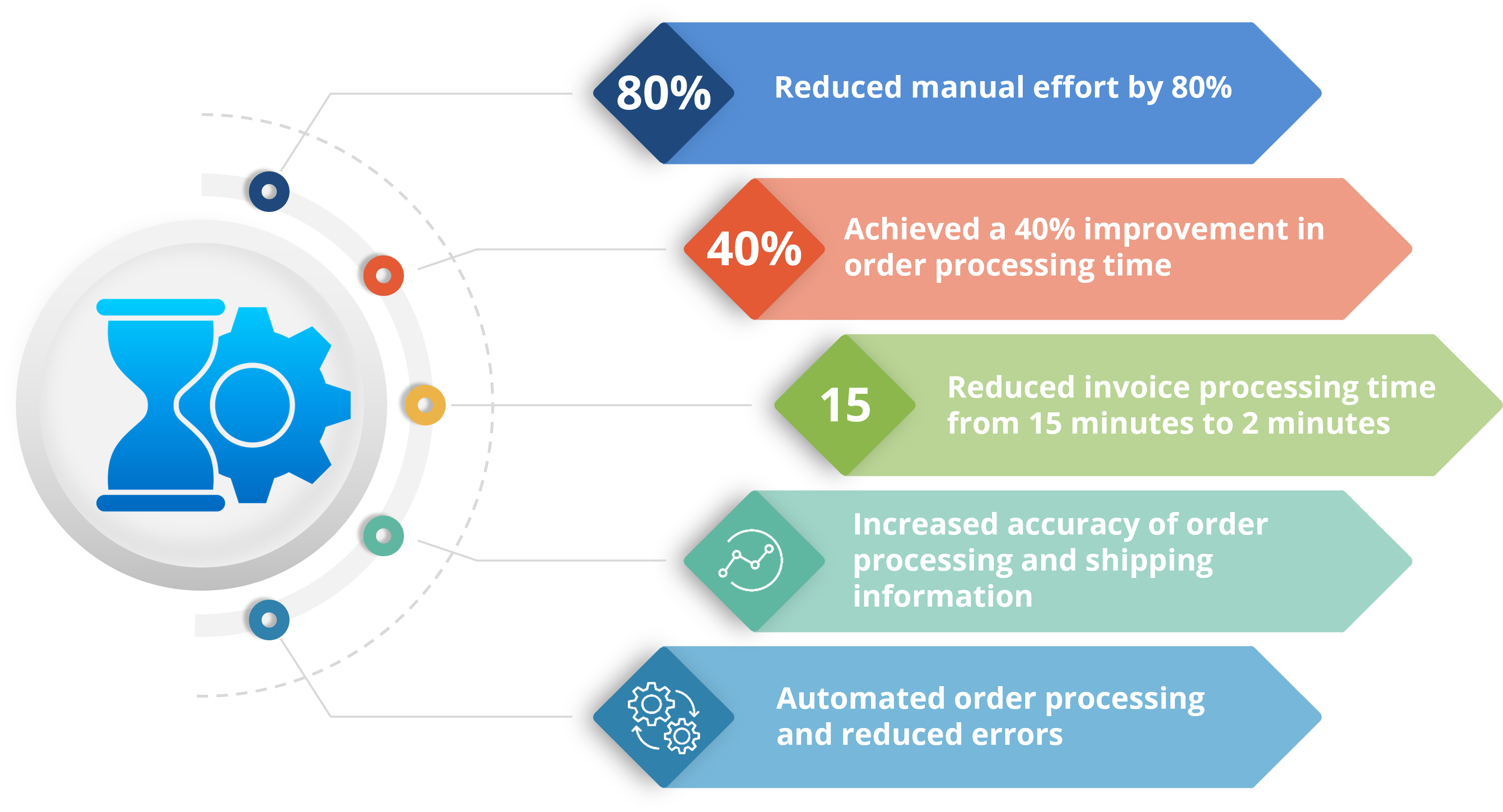

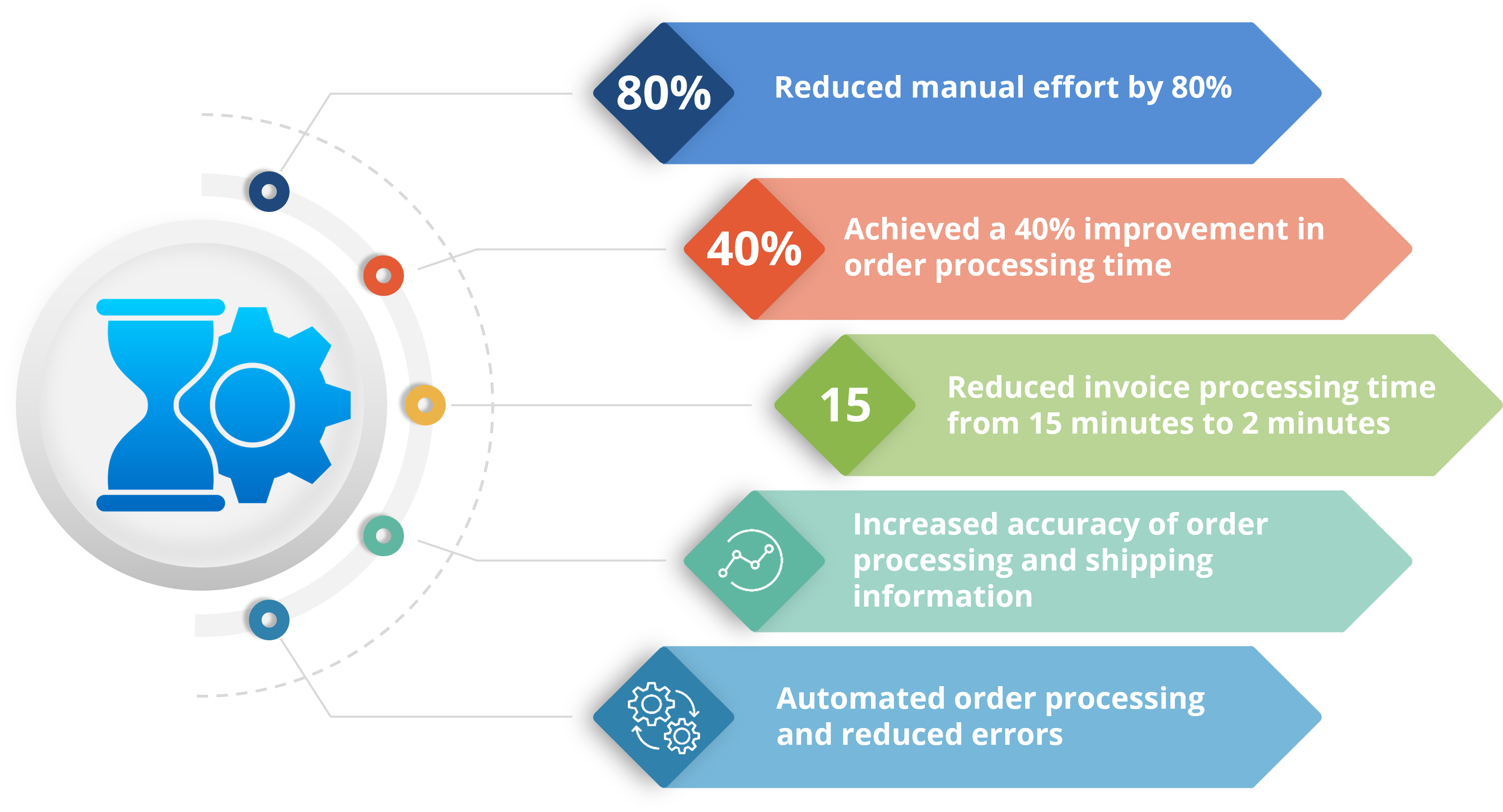

In summary, our technical solution included close collaboration with the business, data migration to HANA, writing LSMW programs to load data to SAP, developing data services jobs for transforming and enriching the data, implementing best practices, validating and profiling data using BODS, preparing technical specifications and knowledge transfer documents, installing and configuring BODS and other EIM Business Objects product family, and developing SQL scripts for analyzing and validating the data, and developing process layer using ABAP / LSMW, Oracle RDBMS, SQL Server, and SAP HANA. These efforts allowed us to effectively migrate our data, improve our existing business processes, and achieve significant business benefits through increased efficiency and improved data accuracy.